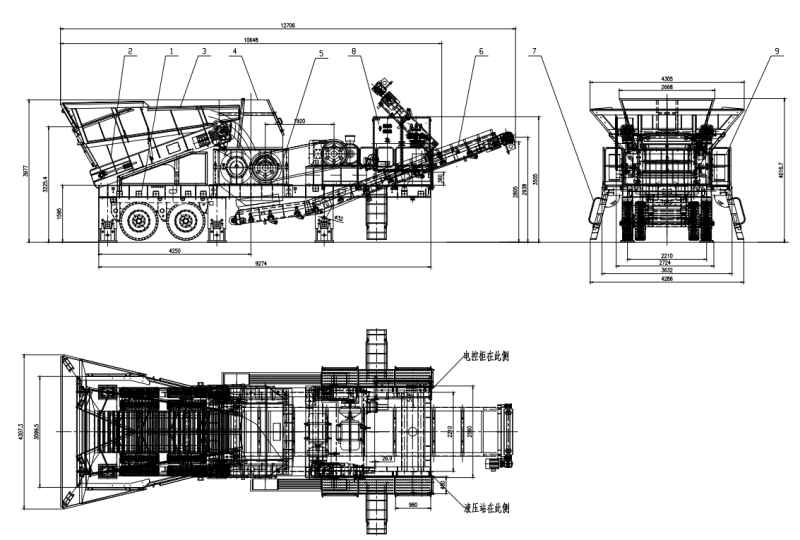

Mobile Crusher Station Of Jaw/Impact/Hammer/Cone/Screen

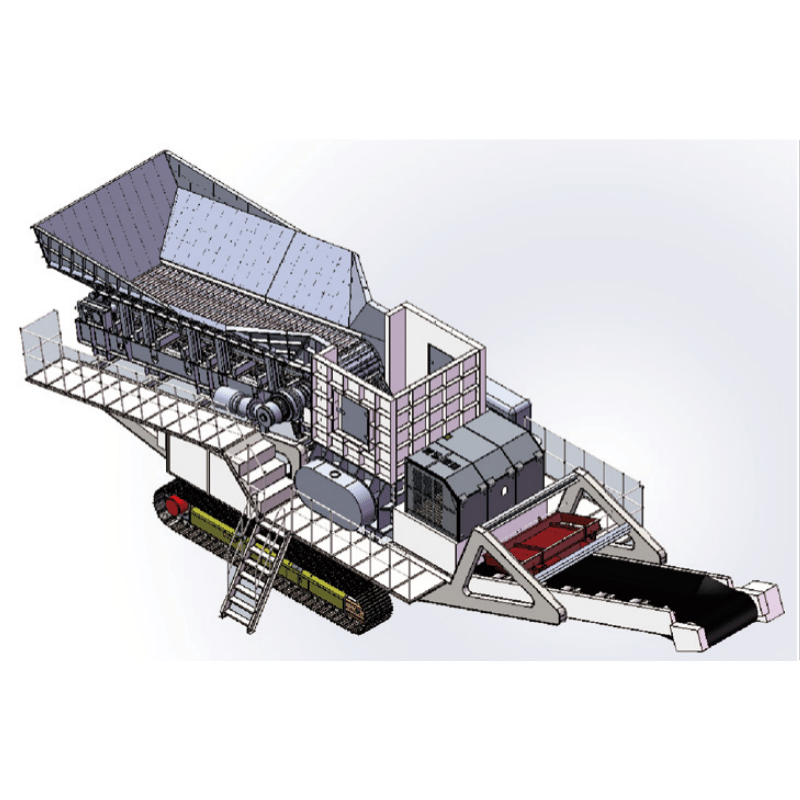

MOBILE CRUSHER STATION STRUCTURE

1: frame

2: apron feeder

3: storage bin

4: crusher hopper

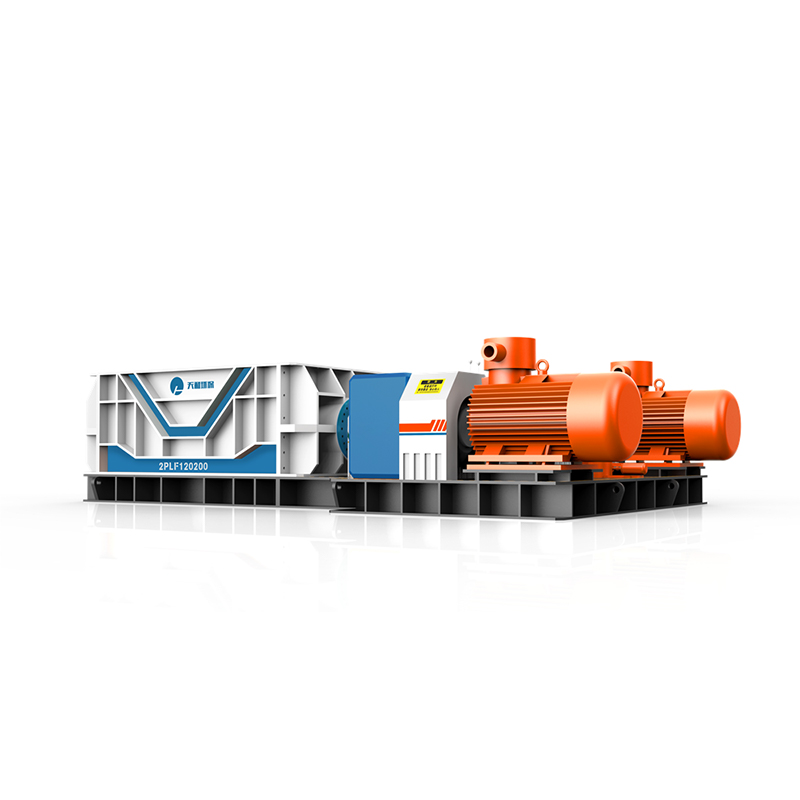

5: double roller crusher

6: discharge belt conveyor

7: platform guardrail climbing ladder

8: electric control cabinet

9: hydraulic station

MOBILE CRUSHER STATION CHARACTERISTICS:

- Main crusher adopts 2DSKP series double teethed roller crusher for secondary crushing and shaping of limestone, of which can reduce over crushing rate to the greatest extent, improve the lump rate of products 40-90mm or 20-40mm limestone rotary kiln feed products, with large process capacity, high lump rate, high efficiency. 2DSKP series double toothed roller crusher under the force of shear, tensile crushing effect, greatly reduce the long strip, sheet material, powerful promoted the sales of finished goods, to ensure the quality of the downstream of finished goods, improve the whole production efficiency of the whole production line, achieve the optimal use of limestone resources.

- It can provide more flexible process configuration according to the customer's requirements for material types and products in the process, and meet various requirements of users such as mobile crushing and mobile screening. According to different crushing process requirements, it can be composed of "first crushing and then screening", or "first screening and then crushing" process.

- The integrated unit equipment installation form eliminates the complicated site infrastructure installation work of split components, and reduces the consumption of materials and man-hours;The reasonable and compact space layout of the unit improves the flexibility of site stationing.

MOBILE CRUSHER STATION TECHNICAL FEATURES

Belt conveyor :

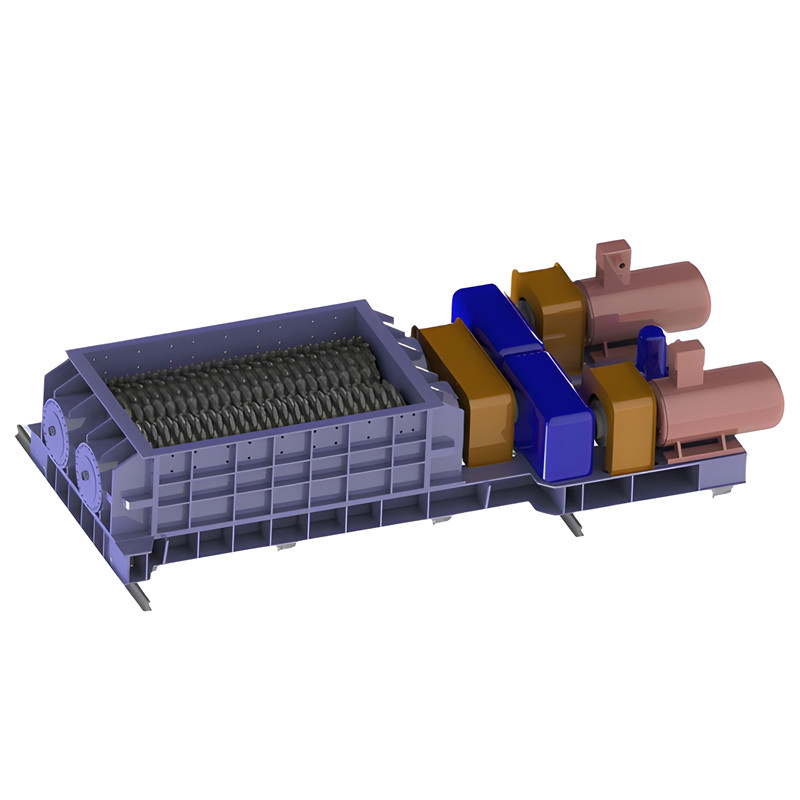

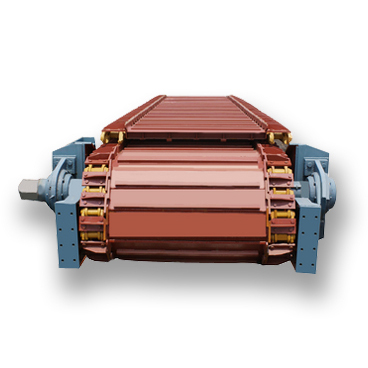

There are fixed type and mobile type, with simple structure and high efficiency. Continuous conveying machinery with flexible conveyor belt as material carrying and traction member. An endless conveyor belt loops around the drive and redirection pulleys. The upper and lower branches between the two rollers are each supported by several idlers. The material is placed on the upper branch, and the frictional force between the driving roller and the belt is used to drag the conveyor belt and the material to run. It is suitable for conveying bulk materials and finished articles in horizontal and inclined directions, and can also be used in assembly lines for certain process operations. Simple structure, stable and reliable work, strong adaptability to materials, large conveying capacity, low power consumption, and wide application.

This product adopts a new belt conveyor structure. The two sides of the belt conveyor of this structure use steel plate bending parts as the main support, and the appearance is more flat and neat, and it is very powerful. The inner belt idler adopts a small diameter idler, which reduces the space occupation and makes the whole belt conveyor more compact. In terms of power, the motor reducer structure is selected, which avoids the problems of excessively large diameter and heavy quality of the drum caused by the traditional electric drum structure, and the overall is more harmonious and beautiful.

Hydraulic lift leg:

The hydraulic outriggers are controlled up and down by manual valves. During transportation, the hydraulic cylinders are raised and the outriggers are mechanically fixed by pins, which is convenient for transportation; when the truck is moved in place and normal production is required, the hydraulic cylinders are lowered to make the whole vehicle more stable. Since most of the weight of the whole vehicle is concentrated in the middle section, the 4 outriggers at the head and rear of the whole vehicle are first raised/lowered during operation, and then the two outriggers in the middle are operated to prevent the outriggers from being damaged due to excessive pressure.

Hydraulic oil station:

The hydraulic oil station sends the pressure oil into the hydraulic cylinder, the feeding bin is folded, the upper cover of the feeding port is broken up by counterattack, the unearthed belt is folded and the outrigger hydraulic cylinder is lifted and lowered. It should be noted that when using the hydraulic station to lift the hydraulic outriggers, due to the high oil pressure in the entire hydraulic system, other on-board hydraulic components cannot be used to prevent other hydraulic components from being damaged.

The hydraulic oil tank is equipped with observation glass, oil level sensor and temperature sensor. When the oil level is lower than the set limit, the oil level sensor automatically closes the vibrating feed chute.

The temperature sensor also does the same when the oil temperature is too high. There is a delay of about 30 seconds in closing the hydraulic system. The capacity of the fuel tank is 480 liters. When filling the hydraulic tank, keep a distance of 10 cm between the oil level and the upper edge of the tank. The drain valve is located at the bottom of the tank. On the other hand, the pressure oil can be sent into the hydraulic cylinder, the feeding bin is folded, and the upper cover of the feeding port and the unearthed belt are folded by counterattack. In order to prevent the hydraulic oil from overheating, there is a special fan to cool it down.

Work platform:

The working platform is connected to the feeding port of the feeder and the placement platform of the diesel generator set, which enables the operator to reach all corners of the vehicle conveniently and safely to monitor the remote rotation of the equipment; however, it can also be used for equipment maintenance and maintenance when there is a problem with the equipment. System calibration check. The working platform is fixed to the system and does not need to be removed during transport.

Control system:

All equipment operations of this product can be completed through the touch screen, providing one-key start and stop functions, and the entire vehicle automatically starts and stops the equipment in sequence, and normal production can be operated without work experience. The touch screen is menu-oriented, and you can get started quickly. You can understand the working information of the required equipment through the touch screen: the speed of the crusher, the frequency of the feeder, the temperature of the engine oil and so on. At the same time, the operation of the equipment is monitored, and the vehicle can be controlled through the touch screen when needed. The outside of the touch screen is protected by a dust-proof electric control cabinet, which can ensure that the touch screen can work stably for a long time under harsh working conditions. The touch screen is attached to the side panel of the lower part of the corridor, and the operation is safe and dangerous.